Ten Lessons to Consider Before You Launch Your Kickstarter Campaign

This is the 2nd post in a series explaining how we launched our first product and ultimately our business.

Sign up for our mailing list and we will shoot these lessons learned right to your inbox :)

We knew right away that we wanted to use crowdfunding to launch our first product. There is so much upside to crowdfunding, and very little downside. If your funding goal is hit or exceeded, you get a huge influx of cash (before you've even bent metal to produce your product). This is such an advantage for brand new companies that are, by nature, cash limited. Some other great benefits include low barrier of entry, awesome exposure (if promoted properly), validation of demand/price point, and real-time feedback.

But before you launch your Kickstarter campaign there are some key things you need to consider. First and foremost, very seldom (if ever) do projects that are just 'thrown' onto a crowdfunding site get funded. Launching a rock-star Kickstarter campaign takes planning, investment, planning, hustling, and more planning. Having launched two campaigns on Kickstarter (one that went 189% funded and one that was never going to close on its goal), we have come to understand what it takes to be successful at crowdfunding. Instead of breaking down each past campaign separately, we thought it would be cool to share with you the steps we are going to take when we launch our next product (the world's most versatile phone stand).

1. Start Sharing

I mean RIGHT NOW! "But I'm afraid someone will steal my idea." Really?!? How many times have you had a 'great' idea only to find out someone had started before you? Did you continue on or did you abandon your idea because someone beat you to it? Exactly! People don't like competition, especially when starting something brand new. So start sharing progress, pictures, details, asking questions RIGHT NOW.

2. Get Social

The name of the game is awareness. If you look at the most wildly successful Kickstarter campaigns, they hit their funding goal on day 1! In some cases, it only took a few hours (need example). This is because their potential backers were aware, before the project was even launched. The best way to begin building awareness is through social media. Lean on your personal and professional networks to start. Before we launched Sabine we copped a @7decibels Twitter account, Facebook Fan Page, and a Google+ Page. We then used HootSuite to simultaneously post to all networks. The key is to get your personal network engaged and then have them help you spread the word. This is a quick way to gain traction with social media.

3. Claim Your Domain

Getting a site set up early is key. The internet is getting exponentially bigger and bigger everyday, get on the map ASAP and start adding content about your project. Regularly updated content about your project, with choice keywords inserted where natural, will help you become discoverable through search. You site will also act as your home-base as you prepare to launch your kick-butt Kickstarter campaign. As you post updates about your project share them on your social networks. This will drive folks to your site and hopefully help with the next to-do.

4. Build a Mailing List

One word... MailChimp. Seriously, you need to begin building your email list. Importing your contacts from iCloud or Gmail is a great place to start. After that, include an action form in PLAIN SIGHT on your homepage. Once things start to materialize and you begin getting closer to launch, use MailChimp's awesome mail campaigns to judge the effectiveness of your copy. Unlock A-B testing and that's where the real fun starts. After a few campaigns using A-B testing, you will be a copywriting ninja capable of pumping out engaging content that motivates readers to take action!

5. Get Your Email Legit

When Google decided to dump their free GApps email hosting a new starlet arose... Zoho Mail. They offer multiple email accounts for your custom domain. Get legit, get Zoho Mail.

6. Befriend the Bloggers

Bloggers and columnists are going to be your best friend during your campaign. It's time to start connecting with the bloggers you think would be most interested in covering your product launch. These folks get tons of unsolicited emails everyday. Experiment with subject lines and the text of your emails to see which ones gain traction. The best approach to befriending bloggers is to actually care about them. Put yourself in their shoes, offer some feedback about a recent post of theirs, start the dialog, build rapport, then mention your product. This step is time-consuming and really hard; but be genuine and grind it out... it will pay dividends come launch day.

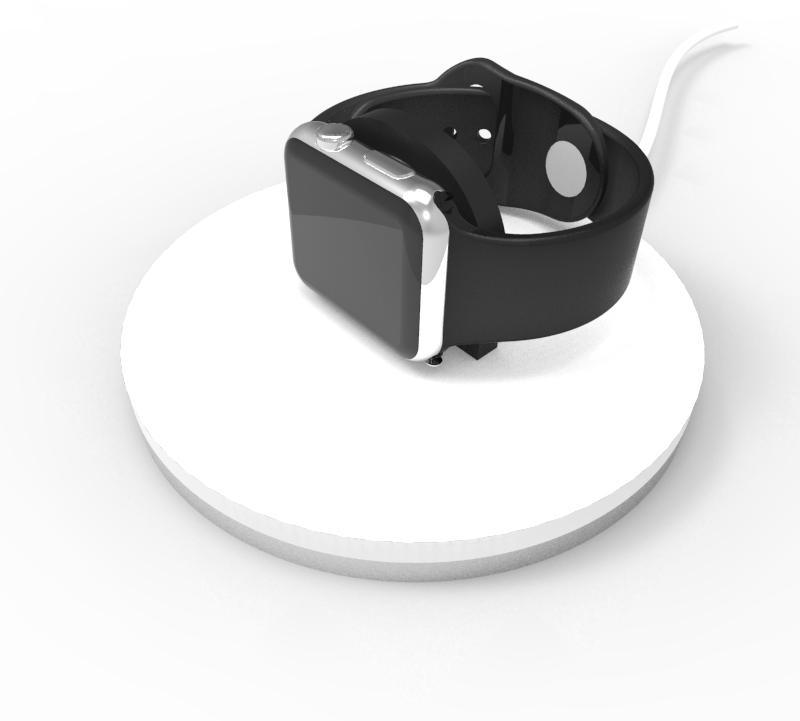

7. Shoot an Awesome Video

The video sells the campaign. Period. The End. This is probably the most important part of the entire campaign so start early. The folks over at StillMotion have an AWESOME series on Storytelling. I could get into what I think makes a compelling video, but I'd rather defer to the experts on this one. Seriously, watch this series BEFORE you start planning your video. We took this very seriously with our first campaign. We hired a local video production firm, the whole nine yards. For round two, we got a bit complacent to be perfectly honest. We used the same production firm, they did a great job... exactly what we asked for. But we didn't put the same thought into the content of the 2nd video. The two videos are embedded below. Take a look for yourself.

Kickstarter Pitch for Original Sabine (189% Funded)

Kickstarter Pitch for Sabine mini (would not have gotten funded, but was cancelled due to production issues)

8. Show and Tell

Get your best prototype and marketing collateral (photos, spec sheets, Kickstarter video, etc) and go on a road show. Seek out brutally honest feedback. This part is key, friends are not going to want to rain on your parade, but press them to provide some critiques. "If there was one thing you would change about the video what would it be?" or "Would you buy this yourself at this price point?" Ask the hard questions and lean on your friends to give you honest feedback. Iterate if needed.

9. Get Organized

Sit down and think about the questions you are going to get regarding your product and come up with canned responses for each of them. This will serve three purposes. 1) It could lead to "bottom of the 9th" improvements for your product before launching. 2) It will be used to populate your FAQ section of your Kickstarter campaign. 3) Finally, it will save you a ton of time once your campaign launches. I don't know how many times I typed out the same email answering the same question. Once we wrote down and saved a response to the 2 or 3 questions we were getting repeatedly, it saved us a ton of time.

10. Sleep

This is the calm before the storm. If you did your homework, and hustled to get here, then your Kickstarter launch is going be one of the wildest, emotional, and fulfilling 20-40 days of your life. Good luck, you'll do great!

Join our mailing list to and we'll send you our tips for during your Kickstarter campaign.

![Production Triforce Photoshoot [Getting Ready for Distribution]](https://images.squarespace-cdn.com/content/v1/5207ae1ce4b008a4a3bc97a7/1423530517863-5B3U9CXDTOVM1Q4EGMWV/triforceDesktop)